Shaft Key Design Formula . Parallel keys are most commonly used. The key and key seat cross section are iso standardized. Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and the hub as shown in the figure. design of key for shaft. In general, shafting up to 3 inches in. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. Most of rotary prime movers either motors or turbines use shaft to transfer the power. shaft keyway shear and yield strength requirements formula and calculator. σm = k fm i. Design tip for shaft and keyways:

from www.chegg.com

Parallel keys are most commonly used. Most of rotary prime movers either motors or turbines use shaft to transfer the power. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. shaft keyway shear and yield strength requirements formula and calculator. In general, shafting up to 3 inches in. σm = k fm i. The key and key seat cross section are iso standardized. Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and the hub as shown in the figure. design of key for shaft. Design tip for shaft and keyways:

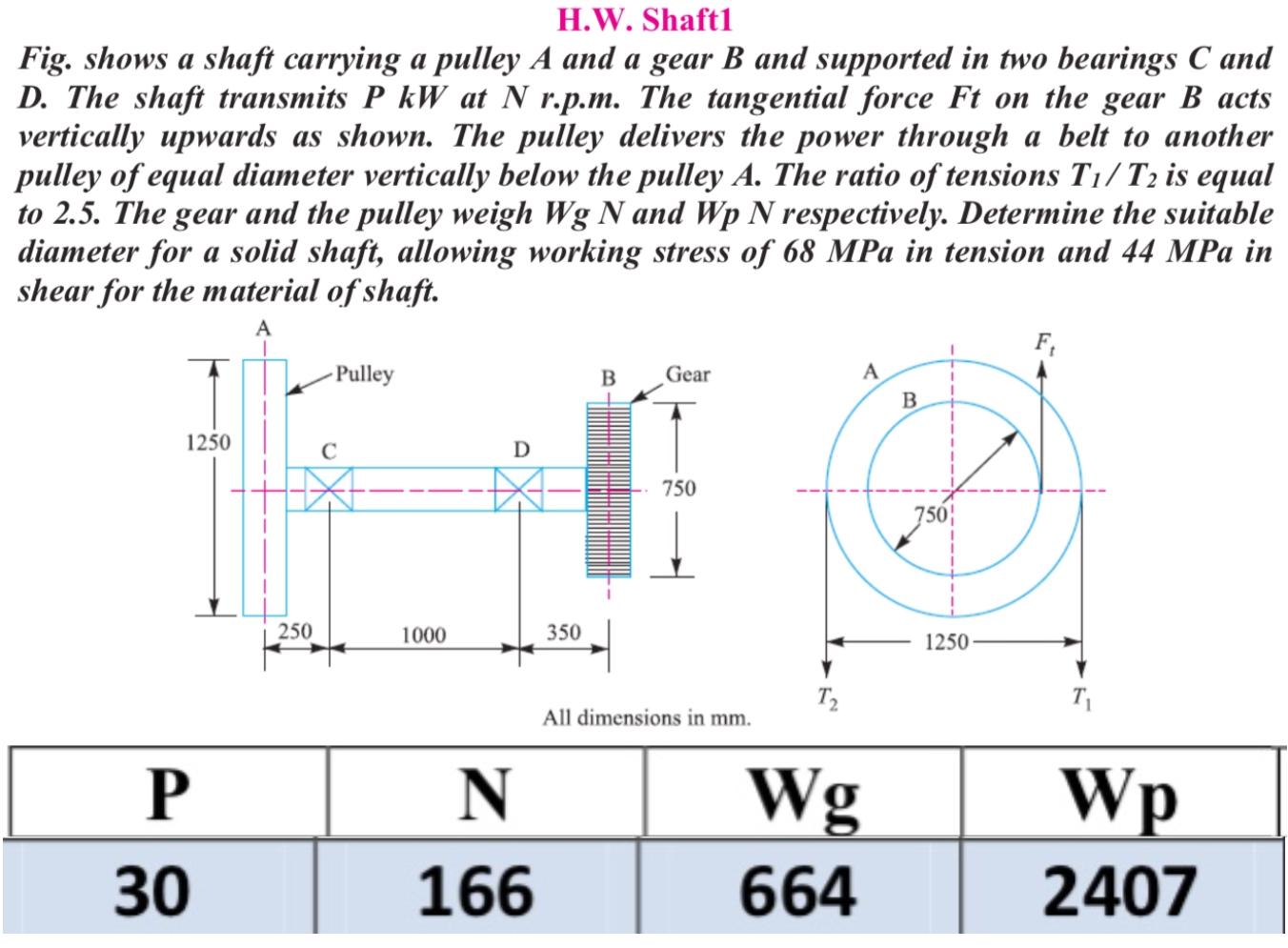

Solved H.W. Shaft1 Fig. shows a shaft carrying a pulley A

Shaft Key Design Formula shaft keyway shear and yield strength requirements formula and calculator. design of key for shaft. Parallel keys are most commonly used. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Design tip for shaft and keyways: this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. shaft keyway shear and yield strength requirements formula and calculator. In general, shafting up to 3 inches in. The key and key seat cross section are iso standardized. Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and the hub as shown in the figure. σm = k fm i.

From www.engineeringtribe.com

Types of shaft keys and their definition. EngineeringTribe Shaft Key Design Formula Parallel keys are most commonly used. σm = k fm i. shaft keyway shear and yield strength requirements formula and calculator. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. In general, shafting up to 3 inches in. The key and key seat. Shaft Key Design Formula.

From mechasource.blogspot.com

an introduction to Keys and Keyways Shaft Key Design Formula In general, shafting up to 3 inches in. σm = k fm i. design of key for shaft. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Design tip for shaft and keyways: shaft keyway shear and yield strength requirements formula and calculator. The key and key seat cross section are. Shaft Key Design Formula.

From www.slideserve.com

PPT Shafts & Keys PowerPoint Presentation, free download ID2991407 Shaft Key Design Formula In general, shafting up to 3 inches in. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Design tip for shaft and keyways: this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. The key and key seat cross section. Shaft Key Design Formula.

From www.engineeringtribe.com

Types of shaft keys and their definition. EngineeringTribe Shaft Key Design Formula shaft keyway shear and yield strength requirements formula and calculator. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Parallel keys are most commonly used. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. Design tip for shaft. Shaft Key Design Formula.

From www.engineeringtribe.com

Types of shaft keys and their definition. EngineeringTribe Shaft Key Design Formula shaft keyway shear and yield strength requirements formula and calculator. The key and key seat cross section are iso standardized. Design tip for shaft and keyways: Parallel keys are most commonly used. In general, shafting up to 3 inches in. σm = k fm i. Consider a parallel sunk key of width w, height h, of length l,. Shaft Key Design Formula.

From slidingmotion.com

Shaft Keys Types, Materials & Applications Your Ultimate Guide Shaft Key Design Formula this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. The key and key seat cross section are iso standardized. Parallel keys are most commonly used. Design tip for shaft and keyways: shaft keyway shear and yield strength requirements formula and calculator. In general, shafting. Shaft Key Design Formula.

From www.youtube.com

Problem on Design of Key Design of Shafts, Keys and Couplings Shaft Key Design Formula Most of rotary prime movers either motors or turbines use shaft to transfer the power. shaft keyway shear and yield strength requirements formula and calculator. Parallel keys are most commonly used. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. The key and key. Shaft Key Design Formula.

From gatesbeltsandapplications.blogspot.com

Gates Belts, Hoses, and Applications Standard & NonStandard Shaft Key Shaft Key Design Formula Design tip for shaft and keyways: Parallel keys are most commonly used. design of key for shaft. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and. Shaft Key Design Formula.

From www.gdandtbasics.com

Keyseats and Keyways GD&T Basics Shaft Key Design Formula this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. σm = k fm i. Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and the hub as shown in the figure. design of key for. Shaft Key Design Formula.

From www.youtube.com

Keys and Its Function Design of Shafts, Keys and Couplings Design Shaft Key Design Formula In general, shafting up to 3 inches in. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Parallel keys are most commonly used. σm = k fm i. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. . Shaft Key Design Formula.

From exowmpjlt.blob.core.windows.net

Shaft Key Design Pdf at Marcia Balser blog Shaft Key Design Formula Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and the hub as shown in the figure. σm = k fm i. The key and key seat cross section are iso standardized. design of key for shaft. Most of rotary prime movers either motors or turbines use shaft to transfer. Shaft Key Design Formula.

From exowmpjlt.blob.core.windows.net

Shaft Key Design Pdf at Marcia Balser blog Shaft Key Design Formula Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and the hub as shown in the figure. σm = k fm i. shaft keyway shear and yield strength requirements formula and calculator. Parallel keys are most commonly used. Design tip for shaft and keyways: design of key for shaft.. Shaft Key Design Formula.

From martinaaryan.blogspot.com

24+ keyway depth calculator MartinAaryan Shaft Key Design Formula In general, shafting up to 3 inches in. Design tip for shaft and keyways: shaft keyway shear and yield strength requirements formula and calculator. Consider a parallel sunk key of width w, height h, of length l, is connecting a shaft and the hub as shown in the figure. Most of rotary prime movers either motors or turbines use. Shaft Key Design Formula.

From www.seiki-ss.biz

Parallel shaft keys explained Seiki Seisakujyo Shaft Key Design Formula Most of rotary prime movers either motors or turbines use shaft to transfer the power. Parallel keys are most commonly used. In general, shafting up to 3 inches in. σm = k fm i. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. Consider. Shaft Key Design Formula.

From www.youtube.com

Problem 1 on Design of Shaft Design of Shafts, Keys and Couplings Shaft Key Design Formula Design tip for shaft and keyways: shaft keyway shear and yield strength requirements formula and calculator. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Parallel keys are most commonly used. The key and key seat cross section are iso standardized. In general, shafting up to 3 inches in. design of key. Shaft Key Design Formula.

From www.chegg.com

Solved H.W. Shaft1 Fig. shows a shaft carrying a pulley A Shaft Key Design Formula The key and key seat cross section are iso standardized. shaft keyway shear and yield strength requirements formula and calculator. this calculator's main function is to quickly and intuitively choose the proper machine key for a given shaft, and to obtain all the. design of key for shaft. In general, shafting up to 3 inches in. Most. Shaft Key Design Formula.

From www.slideserve.com

PPT Shaft Design PowerPoint Presentation ID3955524 Shaft Key Design Formula In general, shafting up to 3 inches in. Most of rotary prime movers either motors or turbines use shaft to transfer the power. shaft keyway shear and yield strength requirements formula and calculator. σm = k fm i. design of key for shaft. this calculator's main function is to quickly and intuitively choose the proper machine. Shaft Key Design Formula.

From exowmpjlt.blob.core.windows.net

Shaft Key Design Pdf at Marcia Balser blog Shaft Key Design Formula In general, shafting up to 3 inches in. Parallel keys are most commonly used. Most of rotary prime movers either motors or turbines use shaft to transfer the power. σm = k fm i. shaft keyway shear and yield strength requirements formula and calculator. design of key for shaft. Design tip for shaft and keyways: The key. Shaft Key Design Formula.